The Significance of RF Shielding in PCB Design

RF Shielding in PCB Design

RF shielding in PCB design is an effective way to reduce electromagnetic interference (EMI). It reduces signal reflections, maximizes power transfer between a source and load, and maintains circuit integrity. But it must be used correctly. If it’s not, the results can be disastrous. Incorrect use of RF shielding can result in high-frequency signal distortion and unwanted emissions, affecting performance. In addition, improper RF shielding can cost 10x more to implement than it should.

An ideal shield would completely enclose the RF noisy components in a metallic cage, but this is not always possible. Unwanted signals can leak through the shielding materials or the shield holes themselves. In addition, shield openings are necessary for thermal cooling, seams, adjustments, and solder points. Noise also escapes from the spaces between ground via-holes on a circuit board. These gaps cause a significant amount of loss and are not as effective as metal cans.

One of the biggest challenges in rf pcb design is avoiding crosstalk and the skin effect, which occur when the board’s components interact with each other. This is caused by a number of factors, including the characteristic impedance, the trace width, and the shielding material’s thickness.

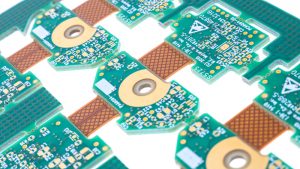

A good PCB stack-up is key to a successful RF PCB design. It needs to include layers with different dielectric constants, and the layers should be oriented properly. The layered structure should be as dense as possible, and the shielding material should have a low Coefficient of Expansion (CCE). The layer stack-up should be designed in such a way that it minimizes impedance variations.

The Significance of RF Shielding in PCB Design

Another factor that impacts RF performance is the loss tangent of the dielectric materials. The tangent angle can change dramatically depending on the frequency, so it must be taken into account when designing a RF PCB. In addition, the materials used must be able to handle high temperatures.

The RF PCB stack-up should also include decoupling capacitors to minimize the voltage on power supply connections, which can cause problems. The placement of these capacitors is important, since they can significantly affect the characteristics of a circuit. The capacitors should be placed in a star configuration, which centralizes all of the circuit’s decoupling capacitance.

RF PCBs are usually constructed using four layers. This is to ensure that the shielding material has sufficient strength to withstand dynamic bending. To achieve this, the conductive glue used in the assembly process must be a low viscosity and a low coefficient of thermal expansion. In addition, the thickness of the shielding material should be a minimum of 40 mils. This will reduce flex circuit board thickness, which impacts the minimum bend capacity of the RF PCB.