What types of industries commonly use rigid flex boards in their products?

rigid flex boards in their products

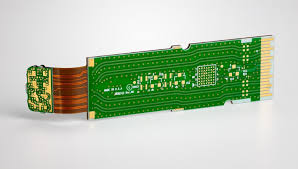

A rigid flex circuit board is a type of printed circuit board that features both a flexible and rigid section. It is a good choice for situations where the board must be able to bend, or it must resist shock and vibration. It is also useful in applications where there are space constraints. It is also highly durable and can withstand high temperatures.

Rigid flex boards are used in various electronic devices from small consumer products like MP3 players and cell phones to advanced avionics/military systems. The primary reason for their popularity is that they can be used to create a more compact and streamlined design. This allows for more efficient use of space and makes the device less bulky and heavy.

In addition, rigid flex board can reduce electromagnetic interference, making them a good choice for high-frequency devices. They are available in single-, double- and multilayers. They are fabricated using either screen printing or photo imaging techniques. They are typically coated with protective films to resist chemicals, oils, hydrocarbon solutions, dust, and debris.

What types of industries commonly use rigid flex boards in their products?

When designing a rigid flex board, it is important to make sure that the copper foil and laminate have anti-tarnish properties. This protects the conductors from oxidation and can prevent electromagnetic interference. It is also critical to route the conductors and traces away from the bending area. This is because mechanical stress can cause them to break down.

During manufacturing, it is essential to use epoxy adhesives that can handle elevated and fluctuating temperatures. These adhesives are also able to resist solvents and other chemicals. They are also flexible and have high bond strength. The etch process is also crucial in a rigid-flex circuit board. There are two popular etching methods: screen printing and photo imaging.

To ensure that the traces and vias are safe from mechanical stress, it is important to avoid placing them in the areas of the board that will be bent. This is because bending the traces can cause them to break down and lead to early failure. This can be avoided by routing the traces parallel to the bending area and avoiding stacked traces that are close together.

The main advantage of rigid-flex circuits is that they eliminate the need for a wire harness. This can save time and money during assembly and testing. Additionally, it can help to improve the quality of the finished product.

It is also important to choose a PCB manufacturer that has the right equipment and fabrication processes. This will ensure that the board is made correctly and is able to withstand the necessary stress. A PCB manufacturer should also have a track record of fabricating rigid-flex circuits.

If you are in need of a rigid-flex PCB, contact Venture today for more information on our services. Our team of experts can help you find the perfect solution for your application. We can provide you with a quote and help you select the best options for your project.