Folding Carton Printing and Finishing Techniques for Eye-Catching Results

Folding Carton Printing

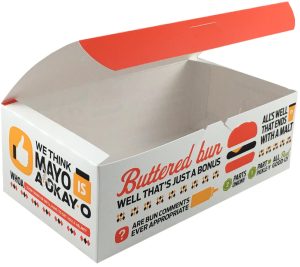

Whether your folding carton is for a high-end luxury product or a household staple, the right packaging partner will take your design from initial conception to structural considerations and final finishing techniques to deliver eye-catching results. Innovative structural designs include clever shapes, openings, and possibilities for decorative touches that elevate your brand on shelves.

Paperboard is the most common material for Folding Cartons, and it’s a versatile option that comes in a range of thicknesses and grades. These grades are specially designed to withstand creasing and offer a superior printing surface. Various coatings and special effects are also available for refining the appearance of a folding carton, giving it additional value and protection to keep its contents secure.

Pre-Design: The first step in any folding carton project is to develop a layout of the desired artwork and imagery. Once the layout is approved, the sheets of paperboard are sheeted to prepare them for the press. This is an important step for the quality of the final packaging, because the grain of the paperboard will run the direction it should when it’s fed into the press.

Folding Carton Printing and Finishing Techniques for Eye-Catching Results

In a highly competitive market, luxury brands seek to differentiate themselves from the competition with unique printed packaging. Several inline embellishment technologies can be integrated into folding cartons, including spot UV coating, embossing, metallic and foil stamping. These processes add visual appeal to a folding carton that makes it stand out from the rest of the competition, promoting a premium brand aesthetic and offering an increased level of protection for the product inside.

The ability to print individual images and copy on folding cartons has revolutionized the industry by allowing companies to speak directly to their target audience with impactful messaging. This method, once used primarily for business cards and printed mailers, has made a unique impact on the folding carton industry by enabling companies to customize short-run printing jobs.

Using inline printing and finishing methods like digital printing and a wide variety of embellishments allows print providers to meet these short-run requirements. These methods can enable smaller target consumer groups to be addressed on a personalized basis, which translates to better lead and delivery times for brand owners.

Spot UV Coating: An alternative to laminating, spot UV coating is applied to the top of a folding carton to create a textured and protective finish. This treatment eliminates the familiar cracking on the top surface of folded cartons that can be caused by digital printing, offering a more robust, longer-lasting, and attractive look for the end product.

Hot Foil Stamping: One of the most popular options for creating a print finish on a folding carton, hot foil stamping uses heat and pressure to apply pigments or metallic inks to the carton. The effect is incredibly expressive and can be combined with any type of color, providing an additional layer of visual interest to the package.